Infroton Factory

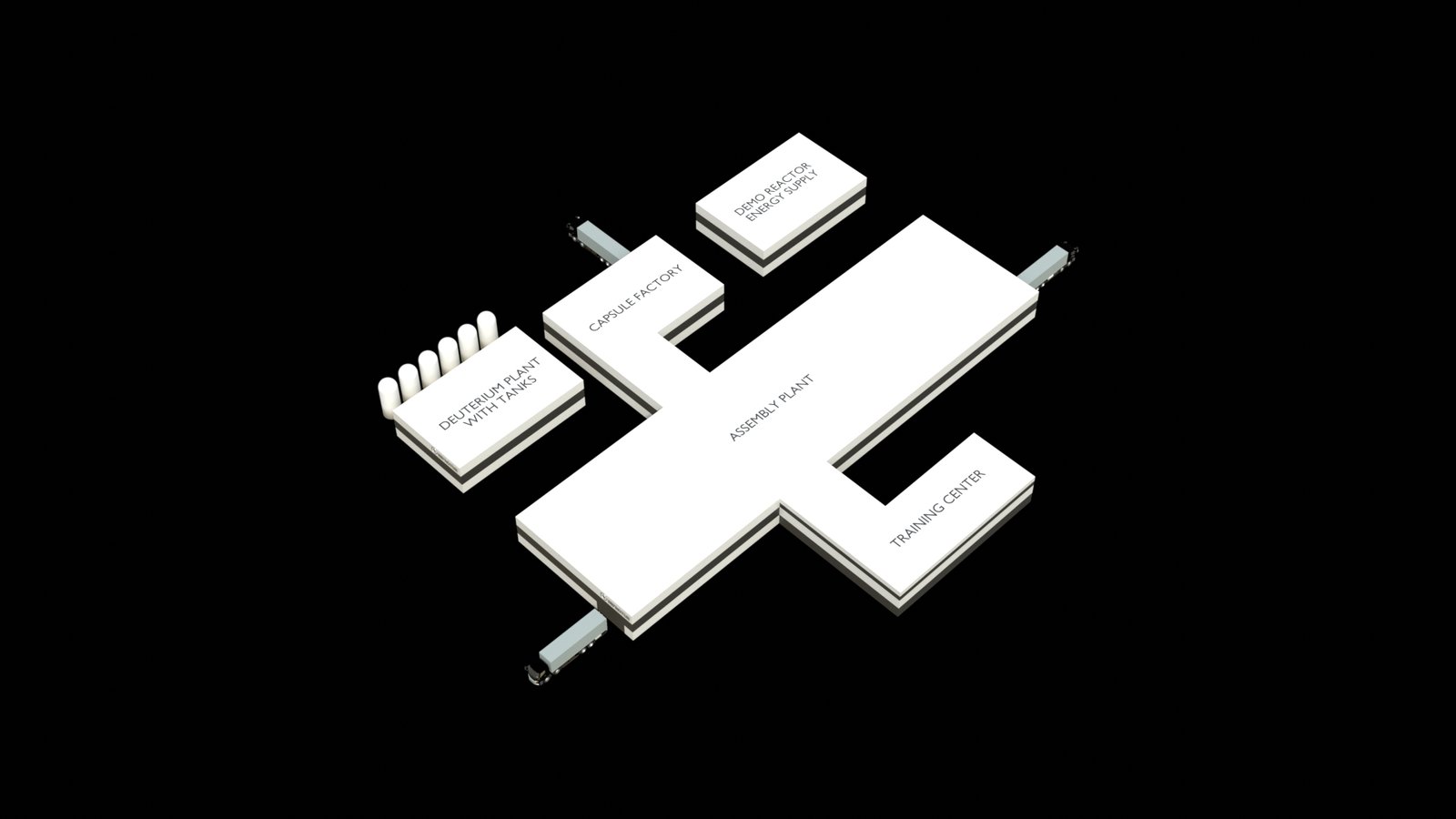

Building Overview

Explore our cutting-edge facilities, designed for efficiency, precision, and innovation.

Infroton Gigafactory - The Global Center of the Fusion Energy Industry

The Infroton Gigafactory is the world's first fully integrated IFE (Inertial Fusion Energy) manufacturing ecosystem. It is designed to produce up to 1,000 containerized 6-30 MWe fusion power plants, 32 billion fuel capsules, and 40,000 kg of deuterium per year. The facility integrates the entire fusion technology stack into one vertically coordinated system: target manufacturing, laser systems, reactors, TPV/Brayton energy converters, and full power-plant assembly. According to our roadmap, the factory reaches full operational capacity between 2033-2037, enabling 1,000+ annual deliveries supported by a global service network.

The Gigafactory is built on four foundational dimensions—structure, technology, processes, and digitalization & AI—creating the world's largest cleanroom-based, robotized fusion manufacturing infrastructure.

Facility Structure (21,000 m²)

- Assembly & Manufacturing Complex

- Laser manufacturing (ceramics, cleanrooms, optics) - 3,000 m²

- Reactor & Brayton energy-converter manufacturing (heavy machinery, welding, W-coating) - 4,000 m²

- TPV cell and module production (PV-style fabrication) - 4,000 m²

- Small power-plant assembly & testing - 3,000 m²

- Warehousing & logistics (ASRS inbound/outbound hubs) - 3,000 m²

- Deuterium Plant with high-pressure storage - 1,000 m²

- Capsule Factory - 1,000 m²

- Demonstration Reactor & Energy Supply Unit - 1,000 m²

-

Training & Innovation Center

- R&D labs, offices, classrooms, and social block - 1,000 m²

Digitalization & AI - The Nervous System of the Factory

- Digital twins for every production line and finished module

- AI-driven quality control, optical diagnostics, and automated inspection

- Predictive maintenance across all critical systems

- Full SCADA + IoT real-time control architecture

AI-centric development is a core element of the Infroton portfolio, supporting fusion propulsion, robotics, autonomous inspection, and large-scale optimization.

How the Gigafactory Preserves Infroton's Market Leadership

The plant's integrated design, high-automation workflows, AI-driven production intelligence, and complete supply-chain ownership create a durable strategic moat. By uniting target production, deuterium supply, laser systems, reactors, diagnostics, and assembly under one roof, Infroton achieves unparalleled cost efficiency, scalability, and speed—advantages competitors cannot replicate without years of manufacturing learning and infrastructure development.